Forward AM: Revolutionizing industry with innovative 3D printing materials

Pioneer in additive manufacturing

Forward AM, a former division of chemical giant BASF, has positioned itself as an undisputed leader in materials for additive manufacturing. Founded on BASF's century-old expertise in chemistry, Forward AM quickly emerged as a key player in the 3D printing industry. The company's mission is to revolutionize industrial production by offering cutting-edge materials for various 3D printing technologies. Thanks to its global R&D network, Forward AM is constantly innovating, pushing back the boundaries of what is possible in additive manufacturing and opening up new perspectives for industries worldwide.

Cutting-edge technology and superior quality

The materials developed by Forward AM are distinguished by their exceptional quality and top-level performance. The company offers a wide range of filaments, powders and resins designed to meet the industry's most stringent requirements. These materials are the fruit of in-depth research and materials engineering expertise, offering optimal mechanical, thermal and chemical properties. The manufacturer places particular emphasis on the development of sustainable, environmentally-friendly materials, thus aligning innovation with ecological responsibility. The consistent quality and high performance of Forward AM products make them the preferred choice of the aerospace, automotive, medical and many other industries.

A diversified range for all industrial needs

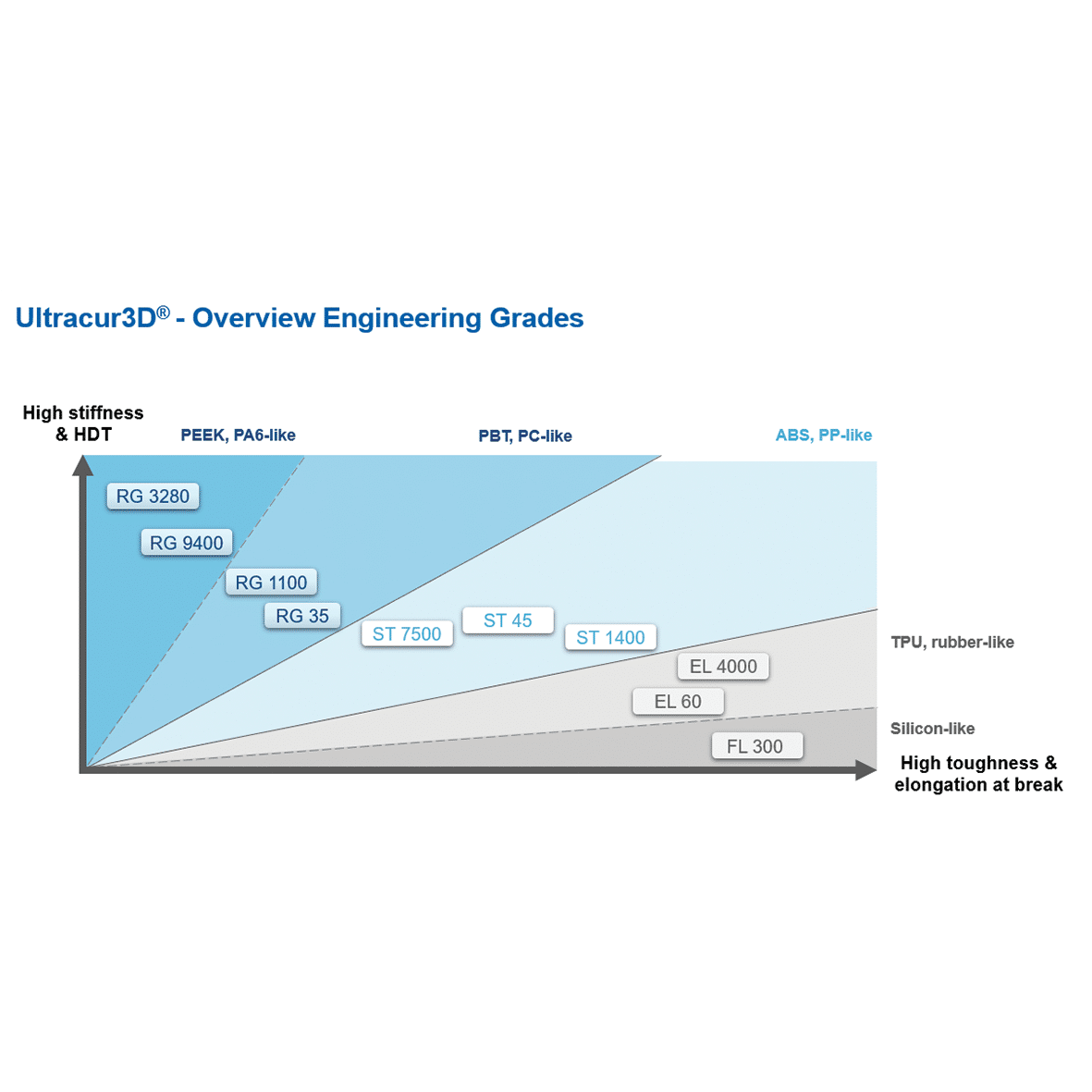

Forward AM offers a comprehensive range of materials to meet a variety of additive manufacturing needs. Their filaments for FDM printing include high-performance polymers. For SLS printing, the Ultrasint range offers high-quality polyamide powders for durable functional parts. For stereolithography and DLP technologies, the manufacturer offers advanced photopolymer resins under the Ultracur3D brand, ideal for the production of precise prototypes and final parts. This product diversity, combined with expert technical support, enables the brand to provide tailor-made solutions for every industrial application, from rapid prototyping to mass production.